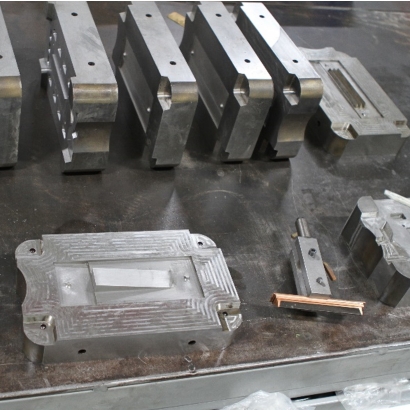

▸Machining Workshop

Part detail processing

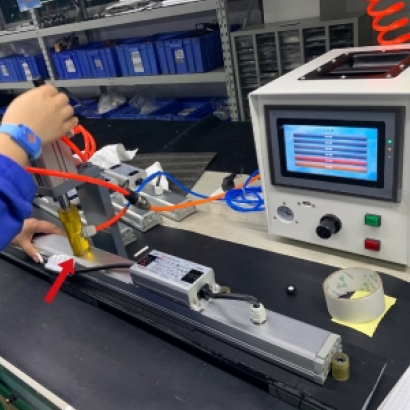

Insist on hand polishing

When the parts cannot be polished by machine, we will use hand polishing. Although it will cost a lot of labor, we insist on this step to ensure that all materials to be baked are smooth and flat, as well as the adhesion and beauty after baking.

When the parts cannot be polished by machine, we will use hand polishing. Although it will cost a lot of labor, we insist on this step to ensure that all materials to be baked are smooth and flat, as well as the adhesion and beauty after baking.